Understanding Bulk Material Handling: A Key Component in Business Success

Bulk material handling is an essential process in various industries, particularly in manufacturing, construction, and logistics. This specialized area involves the management and transportation of large quantities of materials, often in the form of powders, granules, or liquids. Mastering bulk material handling can significantly impact the efficiency, safety, and productivity of business operations. In this extensive article, we will delve deep into what bulk material handling entails, its significance, best practices, and innovative solutions, particularly focusing on the areas of electronics and 3D printing.

What is Bulk Material Handling?

At its core, bulk material handling refers to the techniques and equipment used to manage bulk quantities of material. This process is crucial for industries that deal with raw materials, intermediate goods, or finished products. Here are some key components:

- Storage: Efficient storage solutions, including silos and warehouses, are vital for maintaining a steady supply chain.

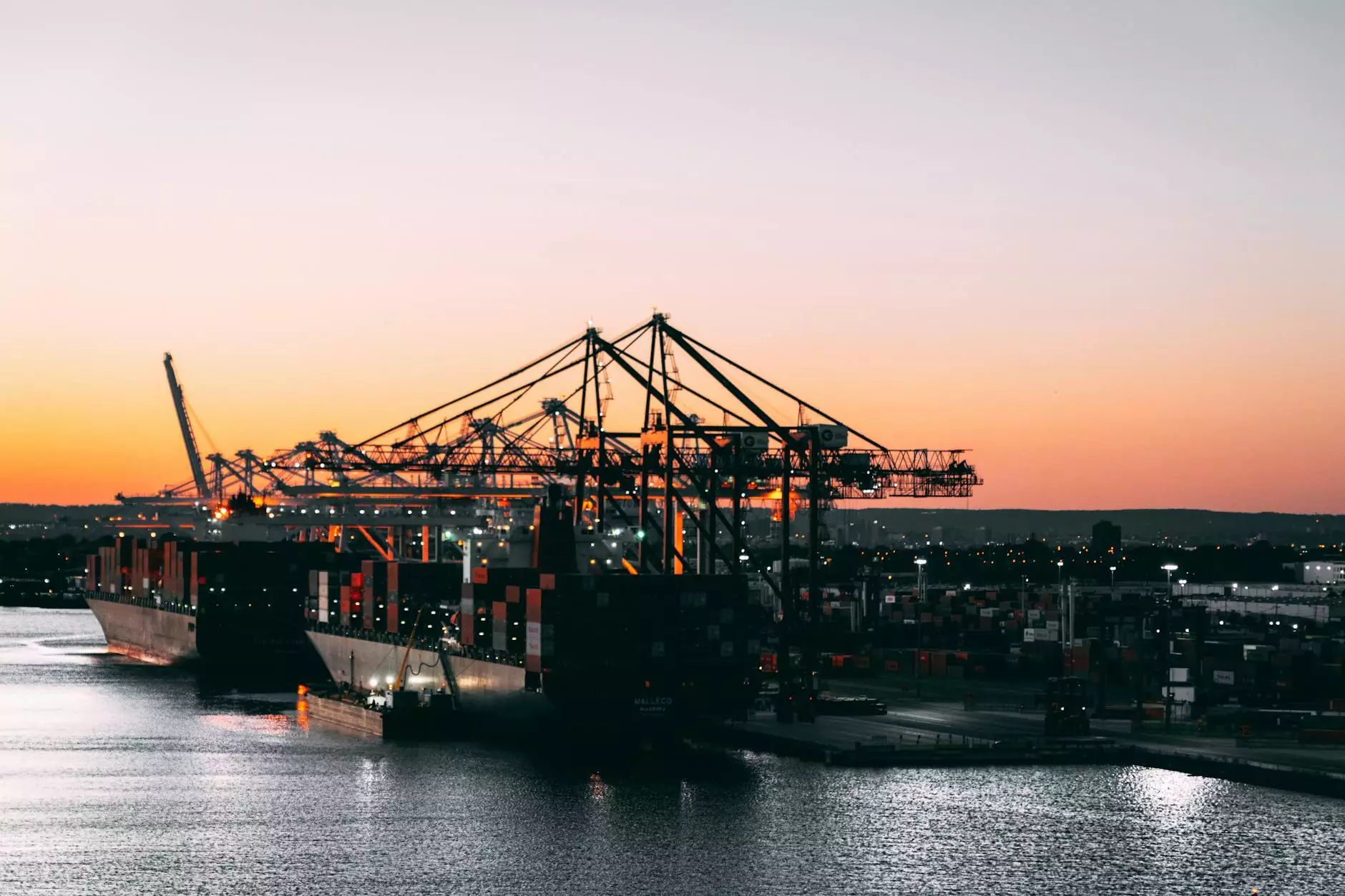

- Transportation: Conveyors, trucks, and ships are integral in moving materials from one place to another.

- Loading and Unloading: Equipment such as cranes and loaders facilitate the transfer of materials to and from storage areas.

- Processing: Often, bulk materials undergo processing steps before they can be used in production.

Why is Bulk Material Handling Important?

Effective bulk material handling is crucial for numerous reasons:

- Cost Efficiency: Streamlined handling processes reduce operational costs significantly.

- Time Savings: Efficient logistics minimize delays and enhance productivity.

- Safety Enhancements: Proper handling reduces the risks associated with material spills and accidents.

- Quality Control: Controlled processes ensure the materials maintain their integrity throughout the process.

The Role of Bulk Material Handling in Electronics

In the electronics sector, bulk material handling plays a pivotal role in the production of electronic components. The intricate nature of electronics manufacturing often requires precise handling of materials such as silicon wafers, metals, and plastics. Here are some areas where effective bulk material handling is critical:

- Supply Chain Management: Real-time inventory management systems help monitor stock levels of essential components, reducing downtime.

- Automation: Utilizing automated systems for loading and unloading can lead to enhanced efficiency and reduced human error.

- Quality Assurance: Implementing strict handling protocols can minimize product defects caused by material mishandling.

Innovative Solutions for Bulk Material Handling in 3D Printing

The growth of 3D printing technologies introduces unique challenges and opportunities in bulk material handling. Below are some innovative approaches:

1. Advanced Material Carriers

Innovations in material carriers designed for powdered metals and plastics have become paramount. These carriers allow for smooth transportation and easy transfer from one processing station to another.

2. Real-time Monitoring Technologies

Integrating real-time monitoring technologies in the handling processes helps businesses keep track of inventory levels and material conditions. This tech can alert operators to any issues before they escalate, ensuring constant operation.

3. Streamlined Workflow Integration

Creating a fully integrated workflow between bulk material handling systems and 3D printing machines can result in significant efficiency gains. Automated systems that transport materials directly to printers can vastly improve production speed and reduce the risk of errors.

Best Practices for Optimizing Bulk Material Handling

To optimize bulk material handling processes, businesses should consider adopting the following best practices:

- Regular Training: Providing training for employees on handling techniques and equipment usage ensures safety and efficiency.

- Investing in Technology: Upgrading to advanced equipment and software can streamline handling processes and enhance data accuracy.

- Conducting Regular Maintenance: Keeping handling equipment well-maintained prevents breakdowns and prolongs service life.

- Implementing Analytics: Using data analytics can reveal inefficiencies and areas for improvement in bulk handling processes.

Challenges in Bulk Material Handling

Although bulk material handling offers numerous advantages, it is not without its challenges. These can include:

- Material Variability: Differences in material properties can complicate handling processes, requiring tailored solutions.

- Compliance with Regulations: Industries often face strict regulatory standards that must be adhered to during material handling.

- Safety Hazards: The nature of handling bulk materials can lead to safety risks that need to be actively mitigated.

The Future of Bulk Material Handling

The future of bulk material handling is set to undergo transformational changes thanks to technological advancements. Key trends to watch include:

1. Automation and Robotics

The use of automated systems and robotics is expected to grow, enhancing the speed and accuracy of material handling processes.

2. Sustainability Practices

Many companies are incorporating sustainable practices in bulk handling to reduce waste and improve environmental footprints.

3. Integration of AI and Machine Learning

Artificial intelligence and machine learning can drive predictive maintenance and optimize logistics operations in real time.

Conclusion

In conclusion, effective bulk material handling is an indispensable aspect of modern industry, influencing both operational efficiency and business success. By embracing innovative solutions, adhering to best practices, and staying abreast of emerging trends, businesses in electronics and 3D printing can significantly enhance their performance and remain competitive in a rapidly evolving marketplace. Emphasizing these core practices will not only optimize current operations but also lay the groundwork for future advancements.

Ultimately, as industries continue to evolve and adapt to new challenges, the principles of bulk material handling will remain at the forefront of operational strategies, ensuring that businesses not only meet the demands of today but are also prepared for the opportunities of tomorrow.