Auto Components Manufacturers: Driving Innovation in the Automotive Industry

The automotive industry is one of the most dynamic and rapidly evolving sectors in the global economy. At the heart of this industry lie the auto components manufacturers, who play a critical role in shaping the future of transportation. In this comprehensive article, we will delve deep into the world of auto components, exploring their significance, trends, innovations, and the growing demand for quality parts in the market today.

The Importance of Auto Components Manufacturers

Auto components manufacturers are the backbone of the automotive sector. They supply essential parts and systems that make vehicles functional and safe. Without these manufacturers, the production of automobiles would come to a halt. Here are some key reasons why their role is so vital:

- Quality Assurance: Manufacturers are responsible for ensuring that the components meet rigorous safety and quality standards.

- Innovation: The auto industry is continuously evolving, and manufacturers are at the forefront of research and development.

- Supply Chain Management: Efficient production and timely delivery are crucial to keeping the automotive market moving smoothly.

- Sustainability: With the rise of eco-friendly vehicles, manufacturers are increasingly focusing on sustainable practices and materials.

Types of Auto Components Manufactured

The range of parts produced by auto components manufacturers is extensive. Here’s a closer look at some of the most critical categories:

1. Engine Components

These include parts like pistons, valves, and camshafts, which are essential for the engine's operation. Robust engine components contribute significantly to a vehicle's performance and longevity.

2. Transmission Systems

The transmission system, which includes gears and drive shafts, is vital for the smooth operation of vehicles. Advanced transmission components help enhance fuel efficiency and driving comfort.

3. Suspension and Steering

These components ensure that vehicles can handle smoothly and safely at various speeds. Manufacturers focus on high-quality shock absorbers, steering gears, and linkages to provide enhanced control and safety.

4. Braking Systems

Critical for safety, braking system components include discs, drums, and pads. Innovations in this area have led to advanced braking technologies like ABS (Anti-lock Braking System) and regenerative braking.

5. Electrical and Electronic Systems

As vehicles become smarter, electronic components have emerged as a vital feature. Parts like sensors, battery management systems, and infotainment technologies innovate the user experience.

Trends in the Auto Components Manufacturing Industry

The auto components manufacturing industry is witnessing several notable trends that are shaping its future:

1. Electric Vehicle (EV) Components

With the shift towards electric vehicles, auto components manufacturers are ramping up production for batteries, electric motors, and charging infrastructure. This market is projected to grow exponentially as more consumers choose electric over conventional vehicles.

2. Smart Manufacturing and Automation

The rise of Industry 4.0 has led manufacturers to integrate smart technologies and automation in their production processes. This advancement enhances productivity, reduces costs, and minimizes human error.

3. Focus on Sustainability

With increasing awareness of environmental issues, manufacturers are adopting sustainable practices. This includes using recycled materials, reducing waste, and creating energy-efficient manufacturing processes.

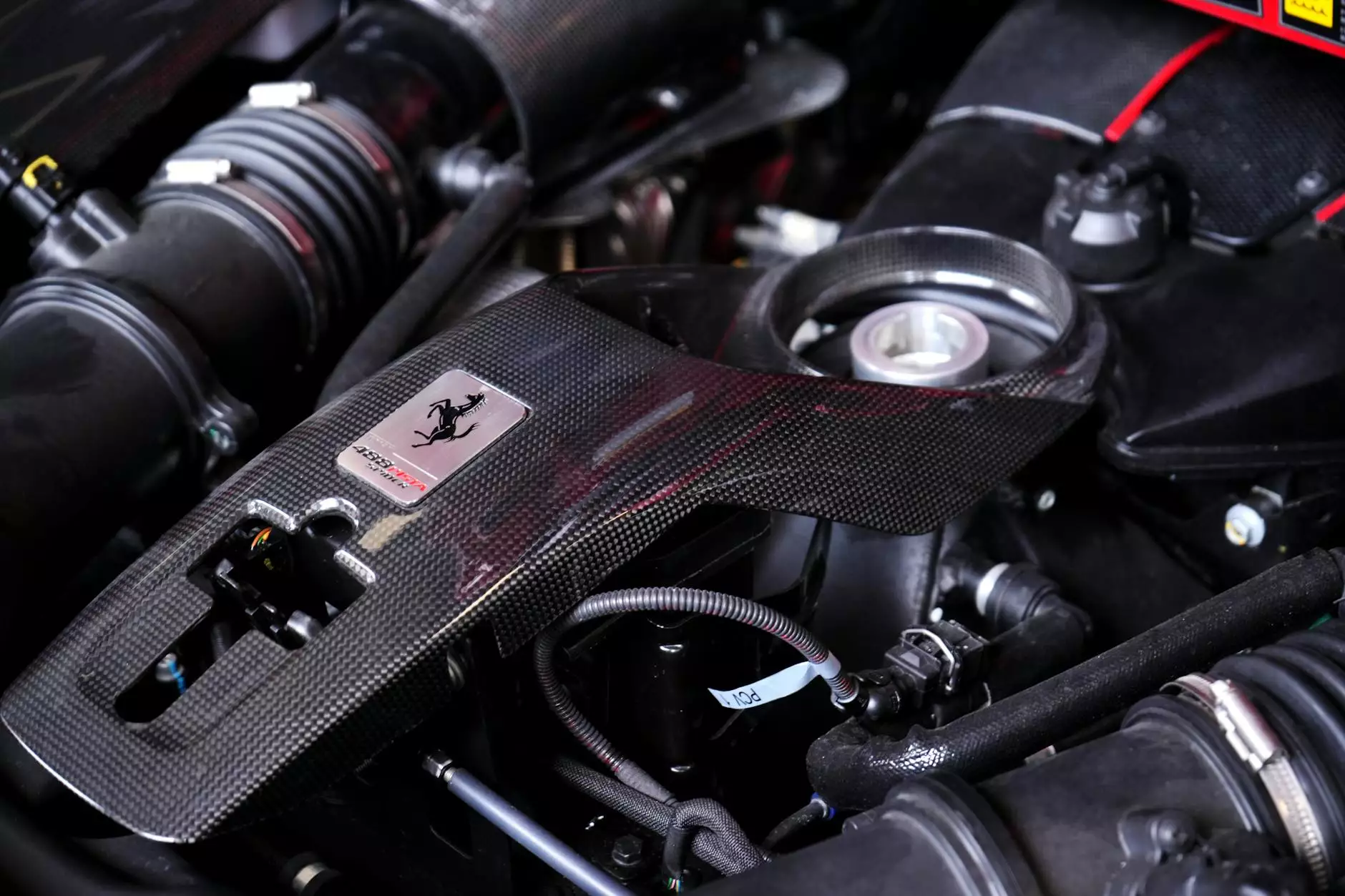

4. Advanced Materials

There is a noticeable shift towards the use of advanced materials like carbon fiber and lightweight composites, which improve fuel efficiency and reduce a vehicle’s overall weight.

The Role of Quality in Auto Components Manufacturing

Quality is paramount in the auto components manufacturing sector. High-quality components not only enhance vehicle performance but also ensure safety and durability. To maintain high standards, manufacturers implement rigorous testing and quality assurance processes, including:

- Material Testing: Ensures that all materials used meet safety and durability standards.

- Performance Testing: Components undergo various stress tests to guarantee reliability under different driving conditions.

- Continuous Improvement: Manufacturers adopt methodologies like Six Sigma to enhance production quality continually.

Challenges Facing Auto Components Manufacturers

While the auto components manufacturing industry presents significant opportunities, it also faces various challenges:

1. Global Supply Chain Disruptions

Events such as pandemics and geopolitical tensions can severely disrupt supply chains, making it challenging for manufacturers to source raw materials and deliver products on time.

2. Rising Labor Costs

As the demand for skilled labor increases, so do the costs associated with hiring and training, which can impact profit margins.

3. Competition from Emerging Markets

With many countries developing their automotive sectors, competition is intensifying, especially from countries with lower production costs.

Choosing the Right Auto Component Manufacturer

When selecting an auto components manufacturer, it's crucial to consider several factors to ensure you partner with a capable provider:

- Experience: Look for a manufacturer with a proven track record in the industry, demonstrating their expertise and reliability.

- Certifications: Ensure that the manufacturer complies with industry standards and holds relevant certifications, such as ISO 9001.

- Technology: Evaluate the technologies and machinery the manufacturer employs to ensure modern and efficient production.

- Customer Support: A manufacturer that offers excellent customer service can significantly enhance your experience and resolve issues promptly.

The Future of Auto Components Manufacturing

The future looks promising for auto components manufacturers, driven by technological advancements and evolving consumer expectations. Here are some trends to watch for:

1. Increased Collaboration

Collaboration between manufacturers, OEMs (Original Equipment Manufacturers), and tech companies will become more integral as the industry moves toward smarter vehicles and sustainability.

2. Industry 4.0 Adoption

Further integration of IoT (Internet of Things), AI (Artificial Intelligence), and big data analytics will revolutionize manufacturing processes, leading to greater efficiency and reduced costs.

3. Globalization of Supply Chains

Manufacturers must balance local and global sourcing strategies to mitigate risks and enhance flexibility in their operations.

Conclusion: Driving Forward with Quality Auto Components

In conclusion, auto components manufacturers serve as a critical engine of growth and innovation in the automotive industry. As we witness rapid advancements in technology and a shift toward sustainable practices, these manufacturers will continue to play an essential role in shaping the future of transportation. By focusing on quality, embracing innovation, and navigating challenges effectively, auto components manufacturers will thrive and drive the industry forward for years to come. For those seeking to learn more or source quality parts, imautoparts.com offers a comprehensive range of auto parts and supplies, delivering value that meets the needs of both consumers and the industry.